What Is a Gigafactory and Why Should You Give a Toss?

Right, let's get this sorted. A gigafactory isn't just some big shed with a flash name cooked up by a marketing department. It’s a colossal, sprawling engine room designed for one primary purpose: churning out millions of lithium-ion batteries at a frankly bonkers scale. Think less about a traditional car plant bolting on doors and more about a high-tech kitchen cooking up the power source for the entire electric car revolution.

So, What Is a Gigafactory Then?

Let's cut through the corporate jargon. The term was popularised by Tesla, and the 'giga' part comes from the 'gigawatt-hour' (GWh) – a unit measuring a frankly eye-watering amount of energy storage. A single gigafactory’s annual output is measured in GWh , signifying a scale of manufacturing that makes conventional factories look like garden sheds in comparison.

The whole point of building something so monstrously large is to achieve massive economies of scale. By bringing the entire battery production process—from refining raw materials to assembling the final battery packs—under one enormous roof, manufacturers can dramatically slash costs. This is the secret sauce to making electric cars less of a pricey status symbol and more of a genuinely affordable option for the average punter.

The Core Mission

A gigafactory is built around a few crucial objectives that guide its design and operation. Without these, it would just be another oversized industrial unit. Its true purpose is far more focused and ambitious.

- Slash Battery Costs: This is the big one. Cheaper batteries directly translate to more affordable EVs for everyone.

- Scale Up Production: Meeting the explosive global demand for electric vehicles requires a ridiculous number of batteries, and these factories are built to deliver them.

- Improve Efficiency: Lumping the supply chain together under one roof cuts down on transport costs, delays, and logistical headaches.

- Drive Innovation: These facilities often become hubs for research and development, pushing the boundaries for the next generation of energy storage.

In essence, a gigafactory is a strategic weapon in the global shift to electric mobility. It’s a clear signal that a company—or even a country—is serious about leaving fossil fuels behind and building the hardware for a cleaner, electric future.

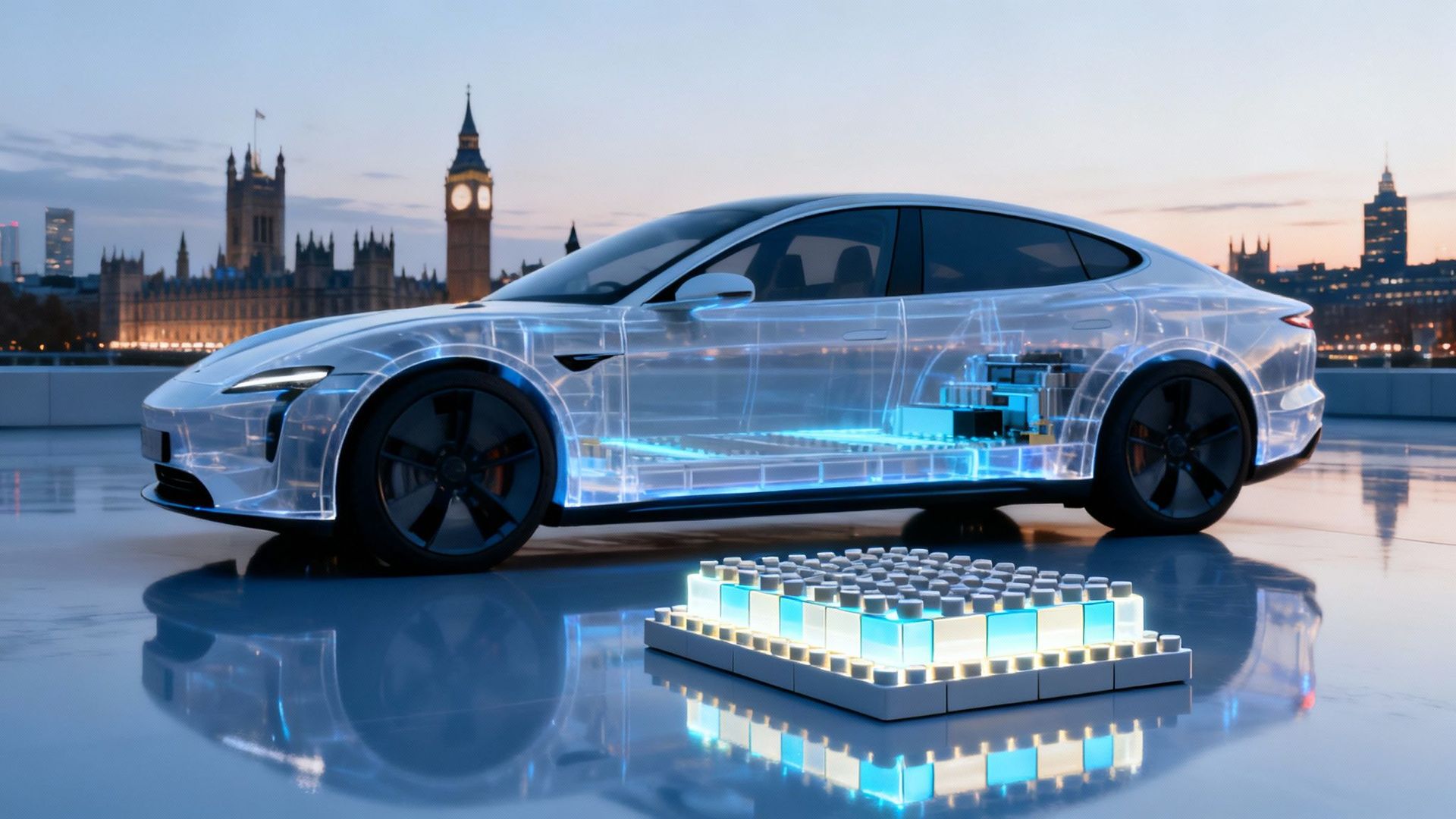

These facilities are the very lifeblood of the EV industry. Grasping how EV batteries work is key to truly appreciating just how important they are.

Why Is Everyone Making Such a Fuss About Them?

So, why are gigafactories suddenly the hot topic for every politician and car company executive with a microphone? It’s pretty simple, really. They aren’t just enormous sheds for building batteries; they represent a crucial move to secure the future of Britain’s car industry. Without them, we’re left high and dry, frankly.

For decades, the car world has relied on sprawling global supply chains. But building an electric car’s most vital, heaviest, and priciest component on the other side of the planet is a logistical nightmare. Shipping millions of batteries across oceans isn't just absurdly expensive; it also pumps emissions into the atmosphere, which rather defeats the point of going electric in the first place.

Building batteries on home turf is about taking back control. It’s about creating proper, skilled jobs in regions that need them and making sure the UK isn’t left begging for scraps while the rest of the world races ahead.

The Strategic Urgency

The demand for EV batteries is absolutely through the roof, and it's only getting bigger. Carmakers are desperate for a reliable, local supply to feed their production lines and meet ambitious net-zero targets. This isn't just a 'nice-to-have'—it's a non-negotiable part of modern industrial strategy.

To put this into perspective, the UK is projected to need around six gigafactories by 2030 just to meet its own domestic demand of 110 GWh per year. That colossal figure is driven almost entirely by the EV market, which is expected to account for a staggering 82% of all UK battery demand by 2040 . The Faraday Institution has some fascinating insights on these projections if you enjoy that sort of thing.

Ultimately, building a domestic battery supply chain is an act of self-preservation. It's about ensuring that cars of the future are not only driven in Britain but also built in Britain, powered by British batteries.

Getting to this scale relies heavily on forward-thinking industrial plans and, let’s be honest, a bit of a shove from Westminster. Understanding the role of government policies in accelerating EV adoption is key to seeing the full picture here. Without that support, these ambitious plans remain just that—plans on a bit of paper.

A Tour of Britain's Gigafactory Contenders

So, who is actually rolling up their sleeves and building these huge battery plants in the UK? The British gigafactory scene isn't exactly a neat and tidy queue. It's more of a scramble, with a few key players wrestling for a foothold in the country's electric future.

Any discussion has to begin in Sunderland, which is home to the UK's original and, for now, only fully operational gigafactory. Run by AESC, this plant has been producing batteries since 2012—long before the term "gigafactory" became trendy. It’s now in the middle of a major expansion to boost its production capacity.

The real giant on the horizon, though, is the Agratas project down in Somerset. This planned facility, backed by Tata (the owners of Jaguar Land Rover), is poised to be an absolute game-changer for the UK's car industry. It's set to dwarf existing operations and create thousands of jobs, securing a vital piece of the EV supply chain right here in Britain.

The Major Projects on the Map

While Sunderland and Somerset get most of the attention, they aren't the only ones in the running. Several other projects are bubbling away, though some have hit more than their fair share of roadblocks.

The UK's battery production landscape is currently dominated by a few major projects, each at different stages of development. Here’s a quick look at where things stand.

UK Gigafactory Projects at a Glance

| Project Name | Location | Lead Company | Status | Target Capacity (GWh) |

|---|---|---|---|---|

| Envision AESC (Phase 2) | Sunderland, Tyne and Wear | Envision AESC | Under Construction | 15.8 |

| Agratas Gigafactory | Bridgwater, Somerset | Agratas (Tata Group) | Planned | 40 |

| West Midlands Gigafactory | Coventry Airport, West Mids | West Midlands Gigafactory | Seeking Investment | Up to 60 |

| Britishvolt (Site Acquired) | Blyth, Northumberland | Recharge Industries | In Planning | TBC (Originally 38) |

This table shows the sheer scale of ambition, particularly from the Agratas project, which represents one of the largest single industrial investments in the UK in decades.

These aren't just factories; they're declarations of intent. Each one represents a massive bet on the future of British manufacturing and a lifeline for local communities hoping for a new industrial dawn.

For towns like Sunderland and Bridgwater, the local impact is enormous. It's not just about construction jobs; it's about creating a new generation of skilled workers, revitalising local economies, and restoring a sense of regional pride.

Of course, the big challenge is turning these blueprints into reality. The pressure is mounting, particularly as manufacturers like Ford are aiming to produce millions of EVs annually and will be desperate for a reliable, local battery supply.

How a Gigafactory Actually Builds a Battery

Ever wondered how a pile of minerals becomes the high-tech powerhouse that moves an electric car? It’s not magic, but it is a mind-bogglingly precise and automated process. Think of a gigafactory as a giant, high-speed bakery for batteries, following a recipe that leaves absolutely zero room for error.

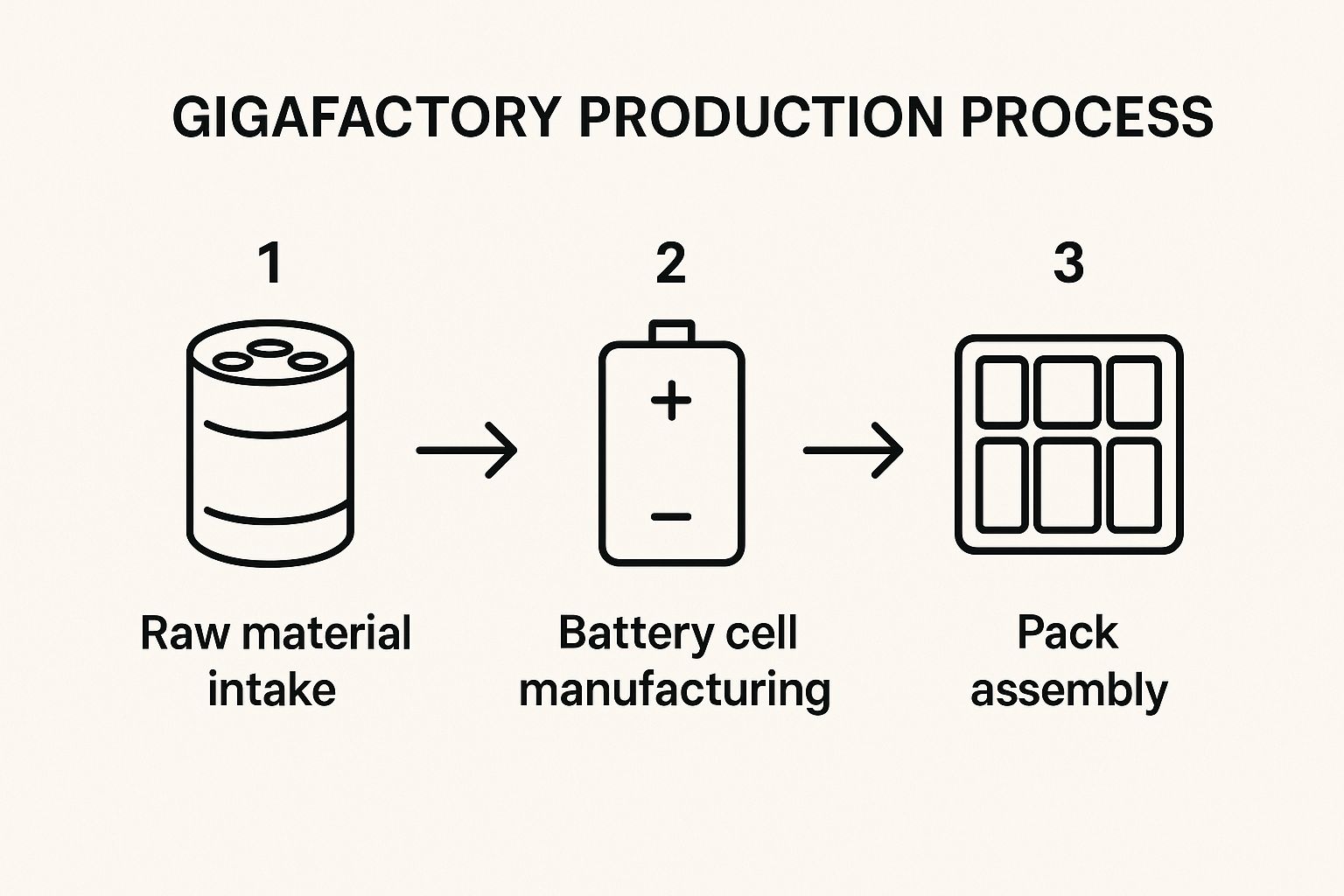

The journey starts when lorry loads of raw materials— lithium, cobalt, nickel, and graphite —arrive at one end of the building. These aren't just tipped into a hopper. They're meticulously refined into a chemical slurry, which is the secret sauce of any battery cell. This stage is a lot like preparing cake batter, except instead of flour and eggs, you’re working with anode and cathode materials.

From Slurry to Swiss Roll

Once the perfect chemical mix is ready, the real manufacturing ballet begins. The anode and cathode slurries are coated onto massive rolls of thin copper and aluminium foil with incredible precision. Imagine icing a cake, but the layers are microscopically thin and perfectly even. Any tiny mistake here can ruin the entire batch, costing a fortune.

The most critical stage is arguably the cell assembly. Here, the coated foils are layered with a separator and then either stacked or, more commonly, wound up tightly like a perfect Swiss roll. This tightly wound component is then packaged into a can, filled with electrolyte, and sealed, creating a single battery cell.

This entire process—from raw material intake to the final pack assembly—is a masterclass in efficiency, as this flow shows.

As you can see, it's a linear, highly integrated system designed to eliminate bottlenecks and maximise output.

Finally, thousands of these individual cells are tested and bundled together into modules. These modules are then connected, fitted with cooling systems and a battery management system (BMS) , and housed in a robust casing. This creates the final battery pack you find under the floor of an EV.

From start to finish, the process is relentlessly automated. Robots do the heavy lifting and high-tech sensors ensure quality at every single step. It’s a symphony of engineering designed to produce millions of identical power units.

The Future of Batteries and Your Next Car

The colossal gigafactories popping up around the globe are impressive, but they’re really just the first draft. The next generation of these facilities won't just be about scale; they'll be about sophistication, producing batteries that make today's technology seem quaint. This isn’t just some dull industry trend—it's a direct preview of what will be powering your next motor.

Right now, the big prize everyone is racing towards is the solid-state battery . By swapping the liquid electrolyte in current lithium-ion cells for a solid material, these batteries promise faster charging, longer lifespans, and a huge leap in safety. We're talking about a battery that could get a full charge in 15 minutes and potentially outlive the vehicle it's in. That’s the kind of progress that changes everything.

A Greener Approach to Power

Beyond the chemistry inside the cells, the gigafactory itself is evolving. The current model—digging massive amounts of raw materials out of the earth—is hitting its limits. The next logical step is to create a circular economy where old batteries aren't waste but a valuable resource.

This is driven by hard-nosed economics, not just green ideals. By building recycling centres right next to production lines, manufacturers can recover valuable metals like lithium and cobalt from spent batteries. This creates a more secure, local supply chain, shielding them from the volatility of global commodity markets.

For you, the driver, this all translates into tangible benefits. Cheaper EVs, thanks to lower manufacturing and material costs. A clearer conscience, knowing your car’s power source is part of a more sustainable cycle. And ultimately, a better driving experience powered by safer, longer-lasting technology.

The car you buy in a few years will be a direct product of these advancements. The gigafactory isn’t just assembling batteries; it’s building the future of how we get about, one cell at a time. The goal is to make the electric vehicle not just a viable alternative, but a genuinely better choice for everyone.

Your Burning Gigafactory Questions Answered

Still got a few questions buzzing around? Good. That means you've been paying attention. Let's tackle some of the most common queries about gigafactories with some straightforward answers.

Think of this as your go-to guide for the things everyone secretly wonders but might be hesitant to ask.

Why Are They Called Gigafactories?

The name is a nod to the ‘ gigawatt-hour ’ (GWh), which is a unit for measuring a truly massive amount of energy—one billion watt-hours, to be exact. Tesla came up with the term because the planned annual battery output of its very first factory was measured in these gigantic units.

In short, it’s a name that shouts scale. These places don't just assemble batteries; they pump out stored power by the gigawatt.

Do They Only Make Batteries for Cars?

Mostly, yes, but not exclusively. While electric cars are without a doubt the main event, taking up the lion's share of battery cells, gigafactories also produce enormous battery units for the national grid.

These energy storage systems (ESS) are vital for a future powered by renewables. They act like giant power banks, storing energy from wind and solar farms to keep the lights on when the sun isn't shining or the wind isn't blowing. So, they’re helping to power both our cars and our homes.

It’s a two-pronged attack on fossil fuels. Gigafactories provide the power for zero-emission transport and the stability for a green energy grid, making them central to the whole net-zero enterprise.

Are Gigafactories Actually Bad for the Planet?

Okay, let's be blunt—it’s complicated. Building batteries is an incredibly energy-hungry process, and mining raw materials like lithium and cobalt has a significant environmental cost. There's no way to sugar-coat that initial footprint.

However, the industry is working hard to clean up its act. Newer gigafactories are increasingly powered by renewable energy sources, and there's a huge push towards recycling old batteries to create a 'closed-loop' supply chain. It's not a perfect system yet, but the whole point is that the long-term benefit of moving away from fossil fuels will far outweigh the impact of manufacturing.

At VoltsMonster , we cut through the noise to bring you the real story on all things EV. For more honest reviews, guides, and industry chat, check out our latest articles at https://www.voltsmonster.com.